The TFT-LCD panel generally speaking is a liquid crystal layer that is sandwiched between two glass substrates, the upper glass substrate is combined with a color filter, and the lower glass is embedded with transistors. The upper glass is bonded with the color filter so that each pixel (Pixel) contains three colors red, blue, and green, and these red, blue and green pixels constitute the image on the panel.

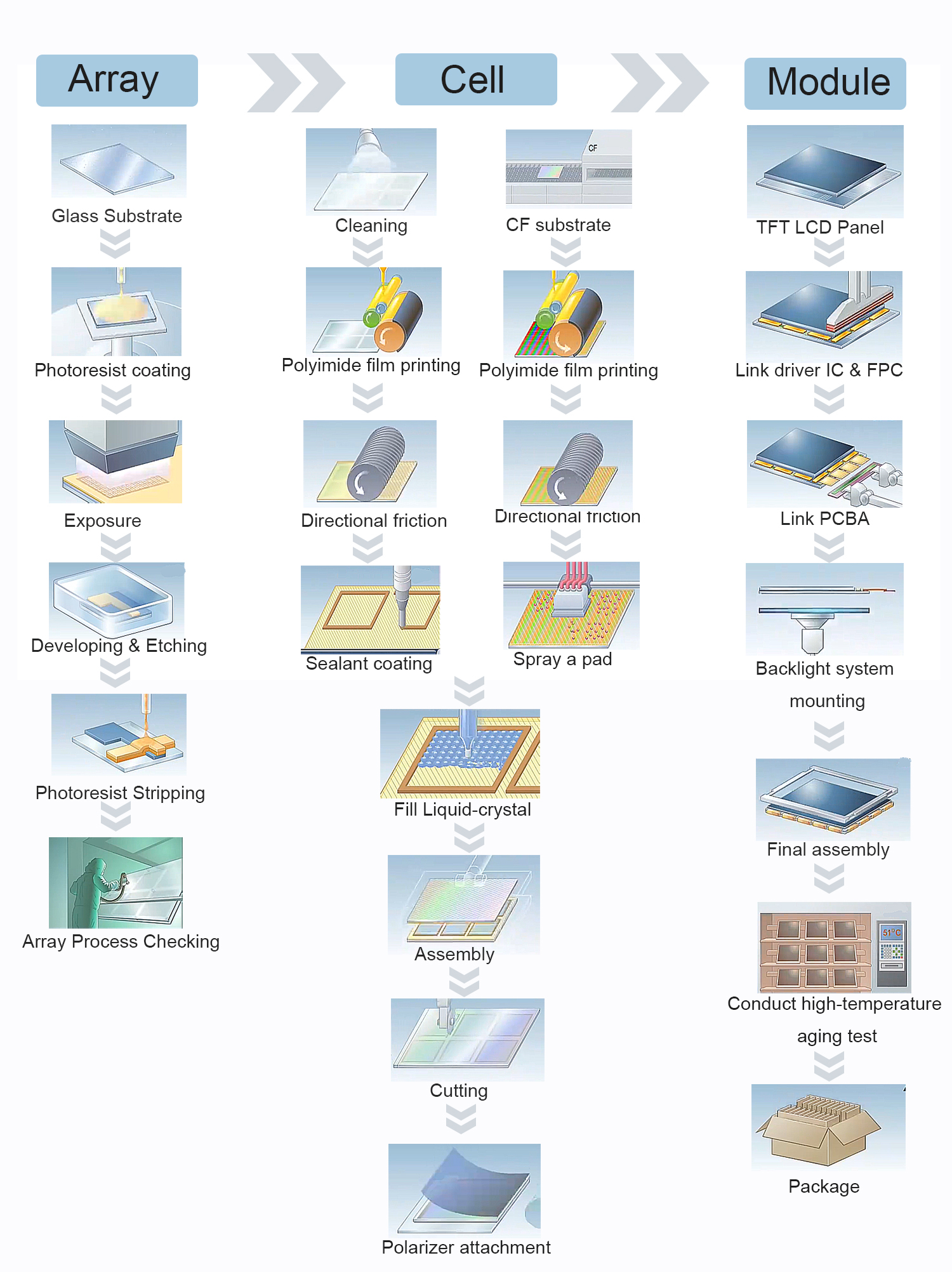

The three main manufacturer processes of TFT-LCD: Array, Cell, Module

Front Array, Middle Cell, Cell is the glass of the front Array as the substrate, combined with the glass substrate of the color filter, and between the two glass substrates Filled with a liquid crystal (LC). The rear module assembly process is the final assembly process of the glass after the Cell process and other accessories such as backlight panels, circuits, and outer frames.

Please check the following picture which shows the whole process of making a TFT LCD. This picture will introduce the whole manufacturing process to you with simple text and a picture description.

1. Array process (array)

1) Before making, we need a piece of glass with a smooth surface and no impurities glass, and must cleaning the glass, then dry it.

2) To coat the glass substrate with a metal film, and the metal material must be placed in a vacuum chamber to comfirm all things clean, and after the special gas on the metal generates plasma, the atoms on the metal will be slammed into the glass, and then will be formed Metal film.

3) After coating the metal film, it is needs to coat a layer of non-conductive layer and semi-conductive layer. In the vacuum chamber, the glass plate is first heated, and then a special gas is sprayed by a high-voltage electric sprayer to let the electrons and the gas Plasma is generated, and after a chemical reaction, a non-conductive layer and a semiconductor layer are formed on the glass

4) After the film is formed, we have to make the pattern of the transistor on the glass. First, enter the yellow light room and spray the photoresist with strong light sensitivity, then put on the photomask to irradiate blue-violet light for exposure, and finally send it to the developing area to spray the developer, which can remove the photoresist after lighting, and let the light The resistance layer is shaped.

5) After the photoresist is shaped, we can perform wet etching by etching to expose the useless film, or dry etching by plasma chemical reaction. After etching, the remaining photoresist is removed with a slippery liquid, and finally The circuit pattern needed to generate the transistor is now.

6) To form a usable thin film transistor, it is necessary to repeat the processes of cleaning, coating, photoresist, exposure, development, etching, photoresist removal, etc. Generally speaking, to manufacture TFT-LCD, it is necessary to repeat 5 to 7 times.

2. Assembly process (Cell)

1) After completing the thin film transistor glass substrate, we will combine the liquid crystal panel. The liquid crystal panel is composed of a transistor glass substrate and a color filter. First, we must wash the glass first, and then proceed to the next step. a step. The entire manufacturing process of TFT-LCD must be in a clean room, so that there will be no impurities inside the display.

2) The color filter is chemically coated to form red, green and blue colors on the glass, neatly arranged and then covered with a layer of conductive film to complete.

3) In the whole process of combination, firstly, we need to coat a layer of chemical film on the glass and color filter covered with transistors, and then perform the alignment action.

4) Before combining the two glass plates, we should evenly fill them with spherical gaps at fixed intervals, so as to prevent the two glass plates from being concave inward after the liquid crystal panel is combined. Usually, when the liquid crystal panel is assembled, one or two gaps will be left to facilitate the subsequent pouring of liquid crystal, and then sealant and conductive glue are used to seal the edges of the two pieces of glass, thus completing the assembly of the glass.

5) After sealing the frame, put the LCD panel into the vacuum chamber, pump the air out of the LCD panel through the gap just reserved, and then pour the liquid crystal into the liquid crystal with the help of atmospheric pressure, and then close the gap. A compound substance between solid and liquid, with the characteristics of regular molecular arrangement.

6) Finally, paste two polarizers in the vertical direction, and the entire LCD panel is completed.

3. Module process (Module)

1) After the polarizer is attached, we start to install DRIVE IC on both sides of the LCD panel. DRIVE IC is a very important driving part, which is used to control the color and brightness of the LCD.

2) Then connect the input end of the DRIVE IC to the circuit board by soldering. In this way, the signal can be sent out smoothly, and then the image on the control panel can be controlled.

3) The light of the LCD panel is emitted from the backlight. Before assembling the backlight, we will first check whether the assembled LCD panel is complete, and then assemble the backlight. The backlight is the light source behind the LCD panel.

4) Finally, lock the CELL and the iron frame with screws.

5) Then we enter the final key test process, and do the aging test on the assembled modules, and screen out the products with poor quality in the state of electrification and high temperature.

6) The products with the best quality can be packaged and shipped.

We provide wholesale and customization of common 1.3″-24″ TFT LCD panels, if you have any projects that need these products, welcome to contact us, besides, we have different size of FLCOS and OLED mini micro-displays in stock, some mall ads bar type LCD display we also could provide, and welcome a bulk production wholesale inquiry.

Recommended reading

How To Prolong The Life Of Your LCD Display?

LCD TFT Display Module List, 1.3″-10.1″ LCD Panel, Manufacturer Price