LCD panels are ubiquitous in today’s technology-driven world, found in everything from smartphones and tablets to televisions and computer monitors. Despite their prevalence and generally high reliability, LCD panels can fail for a variety of reasons. Understanding the common causes of LCD panel failure can help in preventing issues and prolonging the life of these vital devices.

There are several factors that can contribute to LCD panel failure, including:

1. Dead pixels

These are pixels on the screen that do not display any color, and they can be caused by manufacturing defects or physical damage.

One of the most common causes of LCD panel failure is physical damage. LCD panels are made up of several layers, including a glass substrate, polarizers, and liquid crystal material. These components are delicate and can be easily damaged by impact, pressure, or bending. Even a small crack or scratch can disrupt the alignment of the liquid crystals, leading to pixel distortion, dead spots, or complete screen failure.

2. Backlight failure

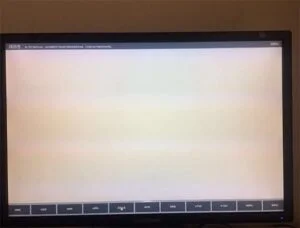

The backlight is a crucial component of an LCD panel, providing the necessary illumination for the display to be visible. If the backlight fails, the screen may appear dim or completely dark, even though the panel itself may still be functioning. Backlight failure can be caused by issues with the LED bulbs, the inverter, or the power supply. Over time, the backlight components can degrade, leading to a gradual dimming of the screen before complete failure.

3. Burn-in

This occurs when a static image is displayed on the screen for an extended period, causing the pixels to become “stuck” and resulting in a permanent image.

This can occur due to power surges, faulty capacitors, or issues with the circuit board. When the electrical components within an LCD panel malfunction, it can result in flickering screens, distorted images, or the screen not powering on at all. In some cases, electrical failures can be caused by manufacturing defects, but more often, they are the result of external factors like unstable power supplies or aging components.

4. Aging and Wear

Like all electronic devices, LCD panels have a finite lifespan. Over time, the materials used in the construction of the panel can degrade, leading to issues like image retention (burn-in), color fading, or the appearance of dead pixels. The backlight can also weaken over time, resulting in a less vibrant display. Regular use and exposure to environmental factors like UV light can accelerate the aging process, ultimately leading to panel failure.

How do I know if my LCD panel has failed?

If your LCD panel has failed, you may notice one or more of the following symptoms:

No display: The most obvious sign of a failed LCD panel is no display. If the screen is completely blank and there is no image or text visible, it is likely that the panel has failed.

Flickering or distorted images: If you see flickering or distorted images on the screen, it could be a sign of a failing LCD panel. The image may appear blurry or distorted, and colors may not display correctly.

Dead pixels: Dead pixels are black spots on the screen that do not change color. They are often a sign of a damaged LCD panel, and if there are a large number of dead pixels, it may be necessary to replace the panel.

Lines or stripes on the screen: If you see lines or stripes on the screen, it could be a sign of a faulty LCD panel. These lines may be horizontal or vertical and can make it difficult to see the image on the screen.

Backlight issues: If the backlight of the LCD panel is not working properly, the screen may appear dim or completely black. In some cases, the backlight may flicker or produce uneven lighting.

Preventive Measures

While some causes of LCD panel failure are unavoidable, there are steps that can be taken to minimize the risk:

- Handle with Care: Avoid applying pressure to the screen and protect the device from drops and impacts.

- Use Stable Power Sources: Ensure that the device is plugged into a stable power supply to prevent electrical issues.

- Keep it Cool: Avoid exposing the device to extreme temperatures, and ensure adequate ventilation to prevent overheating.

- Protect from Moisture: Keep the device dry and avoid using it in humid or wet conditions.

- Regular Maintenance: Regularly clean the screen and ensure that the device is functioning properly to catch any issues early.

While not all failures can be prevented, proper care and maintenance can significantly reduce the likelihood of experiencing issues with an LCD panel.

we recommend that you do not attempt to repair an already damaged LCD panel on your own if it is not necessary to do so, as doing so may damage other components such as the control board and screen protector enclosure, and may further exacerbate the damage to the LCD panel.

Reference Resources: How to identify and repair defects in industrial displays