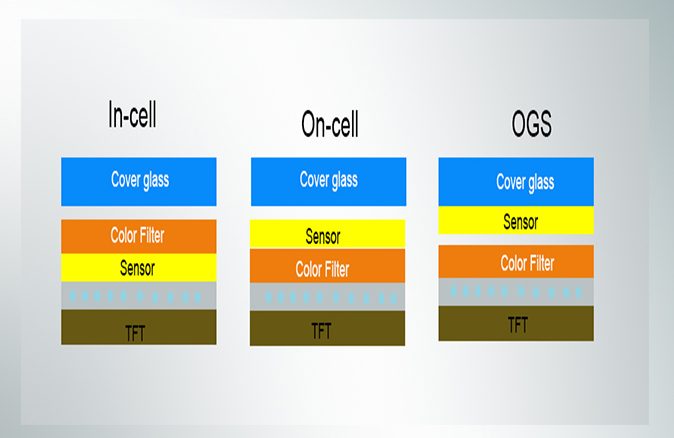

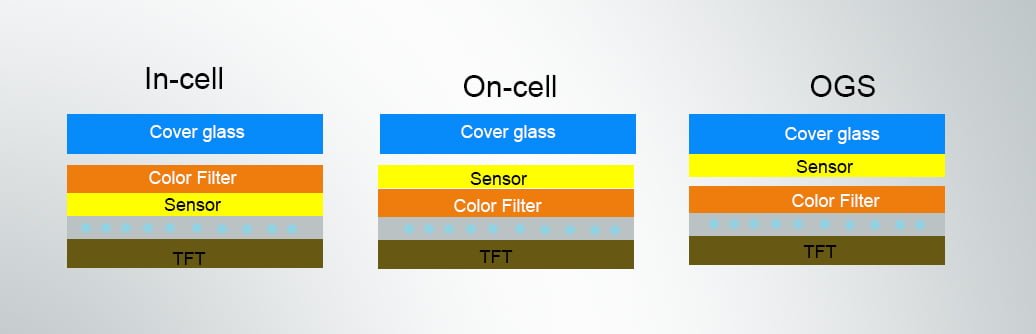

Do you know what we usually call in-cell, on-cell and OGS? What are their characteristics? the following is a brief explanation for you.

The LCD displays can be divided into three parts according to the structure, from top to bottom, They are protective glass, touch part and screen part. What we call in-cell, on-cell and OGS is just technology in the full paste of these three parts. Generally speaking, for an LCD display, especially an LCD touchscreen, two laminations are required, one lamination is between the protective glass and the touch screen, and one lamination is between the screen and the touch part. According to the way of bonding, it can be divided into two types: full paste and frame paste.

- Different Touchscreen With Their Pros And Cons

- Which Is Better: Resistive Touchscreen Or Capacitive Touchscreen?

Full Paste

Full paste means that the display panel and the touchscreen are glued seamlessly with water glue or optical glue. With the full paste technology, there is no air between the display panel and the touchscreen, which can effectively reduce glass reflection and effectively protect the screen from impurities, reduce moisture damage, and increase the working life of the LCD display.

In-Cell

In-Cell simply speaking, it puts the touch sensor (Sensor) in Cell, that is mean embedding the touch sensor function inside the LCD, putting the IoT film under the glass substrate of the display panel, and fusing it with the liquid crystal. Of course, at the same time, the In-Cell screen must be embedded with a supporting touch IC, otherwise, it is easy to cause wrong touch sensing signals or excessive noise.

On-Cell

On-cell refers to the scheme of embedding the touchscreen between the color filter substrate and the polarizer of the screen, that is, a touch sensor is equipped on the liquid crystal panel.

OGS technology

OGS (one glass solution) is also known as TOL technology, which is currently the main application solution on full-paste LCD capacitive touch screens. OGS is a technology that directly implements the touch sensor on the glass cover. It integrates the touch layer and the protective glass and coats the conductive layer of ITO (indium tin oxide) on the inner side of the protective glass to directly coat the protective glass. This saves a piece of glass and one paste work, so makes the LCD touchscreen thinner and lowers the cost. However, since the OGS protective glass and the touch screen are integrated together, it usually needs to be strengthened first, then coated, etched, and finally cut.

RJOYTEK provide one-stop LCD solution, whatever you need full paste or frame paste, they are accept to discuss.

Rjoytek has many years of experience in LCD display manufacturing and solutions, more than 3800 meters of manufacturing area and about 1000 meters of office, 2 professional sales teams and R&D teams, 2 independent factories, which can provide professional solutions for your orders at any time Consulting services and punctual delivery time.

If you are an agent selling all kinds of LCD screens, then we can provide you with competitive prices and inventory support. If you need to develop a new product, then we can provide you with a one-stop LCD solution, Whether it is products, control boards or software support, we are willing to serve you. If you are a manufacturer and only need us to provide products, then we will provide you with high-quality products, design grades according to your requirements, and control product quality.. Welcome to discuss your projects with us!

Our feature products

- TFT LCD display panel includes 1.96″-24″ standard lcd panel or customized

- LCD touchscreen

- Sunlight readable LCD display

- Automotive LCD screen

- Different shapes round LCD and square LCD

- Microdisplay such FLCOS and OLED

More information please send us email!

RJOYTEK LCD PRODUCTS

|

|

|

| AUTOMOTIVE LCD SCREEN | MICRODISPLAY FOR AR/VR | ROUND TFT LCD SCREEN |