Why Do Touchscreen Structures Matter?

The way a touchscreen is assembled affects more than just how it looks—it impacts:

- Touch accuracy

- Display brightness

- Device thickness

- 生産コスト

- Durability and reliability

Choosing the right type can mean smoother user experiences, better battery life, or clearer visibility outdoors. Let’s look at how each type works.

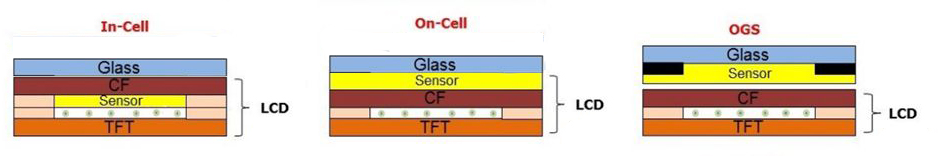

What Is In-Cell Touch Technology?

In-Cell touch technology integrates the touch-sensing layer directly inside the LCD or OLED display panel itself. That means there’s no separate layer on top—it’s all one piece.

How it works:

In In-Cell displays, touch sensors are built into the same layer that handles image display. There are two types:

- TFT In-Cell (common in LCDs)

- AMOLED In-Cell (used in OLED displays)

Pros:

- Very thin and light, perfect for slim devices

- Better touch responsiveness

- Fewer layers = clearer image and improved brightness

- Helps with lower power consumption

Cons:

- Harder and more expensive to manufacture

- Not great for thick screen protectors

- Limited repairability

Best for: Flagship smartphones, tablets, and wearable devices where slimness and clarity matter.

What Is On-Cell Touch Technology?

On-Cell places the touch sensor on top of the LCD panel but beneath the protective glass layer. It’s kind of a middle ground between In-Cell and older touchscreen setups.

How it works:

A transparent touch film is attached directly onto the display surface. It’s close enough to feel responsive, but still technically separate.

Pros:

- Easier to produce than In-Cell

- Still relatively thin and bright

- Supports multi-touch and gestures

Cons:

- Slightly thicker than In-Cell

- Image quality might be a bit lower compared to In-Cell

- Slight air gap can affect glare in sunlight

Best for: Mid-range smartphones, automotive screens, smart appliances, and tablets.

What Is OGS (One Glass Solution)?

OGS stands for One Glass Solution. Here, the touch sensor is printed directly onto the cover glass itself—no extra film or layer.

How it works:

The sensor layer is formed on the back of the glass, eliminating the need for a separate touchscreen substrate. It keeps things simple.

Pros:

- Low cost for high-volume products

- Lighter and more resistant to scratches

- Good display clarity and moderate touch sensitivity

Cons:

- Fragile—if the glass breaks, the touch system fails

- Less suited for outdoor or rugged use

- Lower yields in large-screen sizes

Best for: Entry-level phones, tablets, kiosks, and budget-friendly touch displays.

Quick Comparison Chart

| E Ink | In-Cell | On-Cell | OGS (One Glass Solution) |

|---|---|---|---|

| タッチ感度 | 中程度 | Moderate to High | モデレート |

| 薄さ | Thinnest | 薄型 | 薄型 |

| Display Clarity | 劣る | Very Good | 色彩の鮮やかさ |

| コスト | コスト | モデレート | 低い |

| Repair Difficulty | 中程度 | モデレート | 中程度 |

| Rugged Use | Not Ideal | Acceptable | Less Durable |

| Use Cases | Flagship phones | Smart displays, IoT | Budget devices, POS |

Which One Should You Choose?

It depends on your application:

- Building a high-end mobile device? Go with In-Cell for top performance and minimal thickness.

- Designing an industrial UI or automotive display? On-Cell provides a great balance of clarity and durability.

- Need an affordable screen for consumer electronics or signage? OGS will give you good results without breaking the bank.

Common Questions

What’s the thinnest type of touchscreen?

In-Cell is the slimmest, since the touch function is built right into the display.

Is OGS better than On-Cell?

Not necessarily. OGS is more affordable but may be less durable. On-Cell is more robust and a better fit for mid-range devices.

Can In-Cell be used outdoors?

Yes, but visibility depends on brightness and whether it has anti-glare treatments. In-Cell screens may struggle in direct sunlight unless specially treated.

Which one is easiest to repair?

Probably On-Cell. In-Cell and OGS integrate more components into a single unit, which means higher replacement costs if damaged.

まとめ

Understanding these touchscreen technologies can help you make better design decisions—whether you’re selecting a panel for a rugged industrial tool or the next sleek wearable.

In-Cell, On-Cell, and OGS each bring their own advantages. The best option comes down to what matters most: clarity, cost, size, or durability.