Advanced FOG Bonding Techniques and Innovations

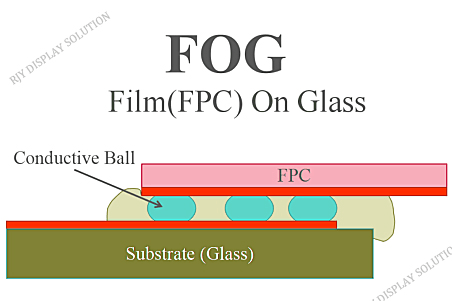

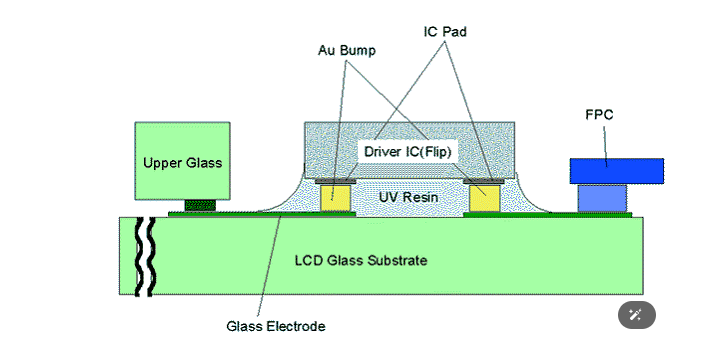

The process mechanically bonds and conducts between the film (FPC) and glass.

FOG, short for Film On Glass, refers to bonding FPC to a glass substrate. While FPC is primarily bonded to glass panels like LCDs, the term FOG applies to any FPC-glass bonding, not just displays.

The bonding method used is thermo compression bonding (ACF crimping) with ACF. Typically, FPCs with a terminal pitch of 80 to 200 μm are bonded. However, we have introduced a high-precision FOG bonding machine capable of handling pitches as small as 26 μm, allowing us to bond various FOGs. For fine-pitch bonding, such as 26 μm, the bonding machine’s capacity must be supported by precise FPC design and material management.

We have extensive experience with ACF materials used in ACF crimping and can perform ACF bonding according to the manufacturer’s recommended conditions. Additionally, we support bonding a wide range of FPC sizes. Please contact us if you have any issues with ACF crimping.

About More

We are committed to developing and manufacturing high-performance, cost-effective, low-failure LCD & OLED panels, and if you are interested in making your equipment less risky to maintain and more competitive in the marketplace, please feel free to contact us for excellent free consulting services, as well as our latest product catalogs and quality quotes.

Our advantage: in addition to providing the fully customized solutions , we can also provide other control boards, these boards and LCD screens can be purchased from us together, one-stop service is our aim.

- We provide customization, including product size, touch screen, digital cable, and control board;

- We have obtained various product certificates and factory certifications, such as ISO9001, ISO45001, REACH, CE, etc;

- We have 2 factories, we can provide fast lead time and fast production time;