How Reflective LCD Displays Work

1. Light Path and Optical Construction

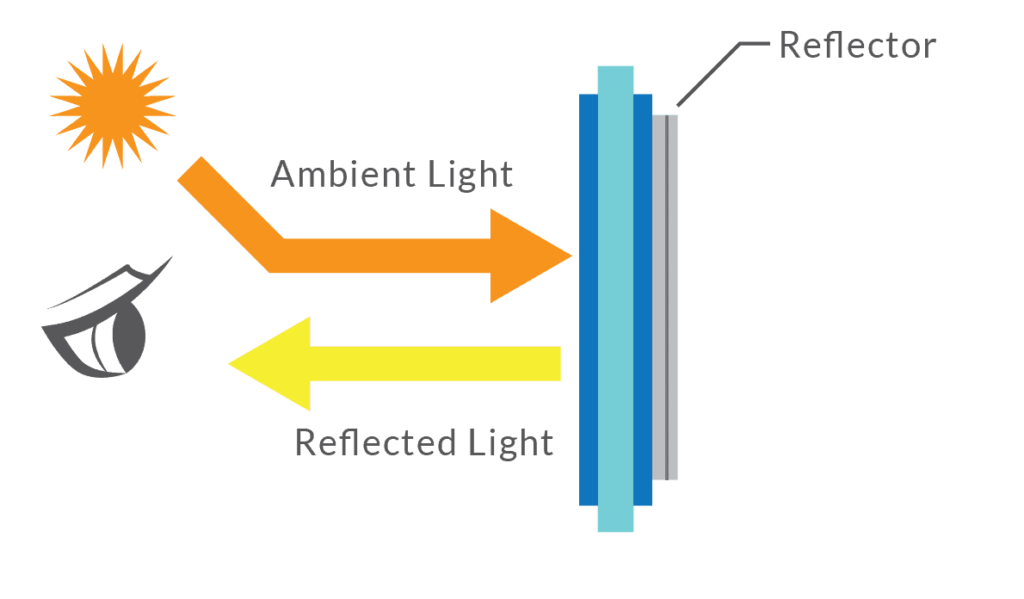

Instead of relying on a white LED, reflective LCDs use a metallic backing layer—typically silver or aluminum—as a mirror behind the liquid crystal cell. Ambient light enters through the front polarizer, passes through the LC layer and color filter, hits the reflector, and then retraces its path back through the filter and polarizer to your eyes. This double-pass makes the image appear more vivid, improving perceived contrast and depth.

2. Cell Structure & Alignment Layers

High-precision alignment is crucial. Both substrates are coated with rubbed-oriented polyimide layers to orient the liquid crystals uniformly. Microscopic spacers maintain a consistent cell gap (usually 3–5 µm), ensuring that the optical response remains even across the entire display.

3. Retardation & Phase Compensation

Some reflective panels include laminated retardation films—such as polymerized reactive mesogen layers ~1 µm thick—that fine-tune the polarization state. Because the light reflects and passes twice, these films effectively double phase-shift control, enhancing contrast and color accuracy.

4. Pixel & Color Filter Design

Monochrome reflective LCDs are relatively simple: a uniform ITO electrode grid atop a mirrored substrate, no need for RGB subpixels. Color variants introduce striped RGB filters above the reflector, but still cannot match the range of color or saturation seen in backlit TFT or OLED panels.

5. Surface Treatment & Polarizer Optimization

To enhance readability outdoors, reflective LCDs often include circular polarizers, anti-glare coatings, and wide-viewing compensators. These reduce reflections and ensure consistent brightness across large viewing angles.

LPRD & Advanced Reflective Technologies

Low-Power Reflective Display (LPRD) modules are a step up, offering better color reproduction and optional low-intensity illumination. Some use MEMS-based micro-cavity interferometric (IMOD) designs, like the Qualcomm Mirasol displays, creating color through optical interference rather than filters.

Notable examples:

- Color reflective panels from BOE or Hannstar, typically 18–20% reflectivity

- Qualcomm’s Mirasol displays using micro-cavity interference

- Sun Vision Display’s full-color reflective LCD prototypes showcased in early 2022

Advantages & Drawbacks

✅ Advantages:

- Excellent sunlight visibility: No backlight needed—natural light suffices

- Ultra-low power consumption: Power only required for pixel updates

- Thin and lightweight: Ideal for wearables or embedded devices

- Highly durable: No heat from backlights, minimal stress on components

⚠️ Drawbacks:

- Ambient light required: Not suitable for dark environments without supplemental lighting

- Limited color gamut: Mostly grayscale, or muted color performance in advanced models

- Design complexity: Requires precision in cell alignment, polarizer installation, and mirror flatness

Key Applications

Reflective LCDs shine in energy-conscious and outdoor-friendly applications:

- Smart wearables (fitness bands, smartwatches)

- Outdoor instrumentation (e-bikes, solar controllers)

- Industrial meters and rugged handheld tools

- Low-power IoT devices needing readable data screens

- Digital shelf labels and e-price tags used in retail

FAQ – Frequently Asked Questions

Q1: How do reflective LCDs show color?

Advanced modules use techniques like micro-cavity structures (e.g., IMOD or Mirasol) or reflective RGB filters. Color saturation is still limited compared to emissive displays.

Q2: Do reflective displays support fast refresh?

Yes—many LPRD modules support up to 30–60 fps, making them usable for simple animations or UIs.

Q3: Are they long-lasting?

Users and field testers have reported consistent performance even after over 10,000 hours of daily use in rugged environments.

Q4: What design challenges exist?

Maintaining consistent cell gap, mirror flatness, and polarization alignment is critical. Small deviations can cause uneven illumination or moiré artifacts.

Q5: Can they be used in darkness?

Only with frontlight modules or supplemental illumination. Transflective or front-lit reflective variants are common solutions.